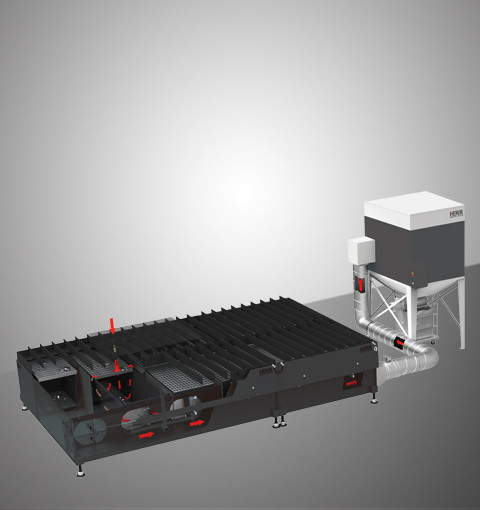

PlasVent cutting table

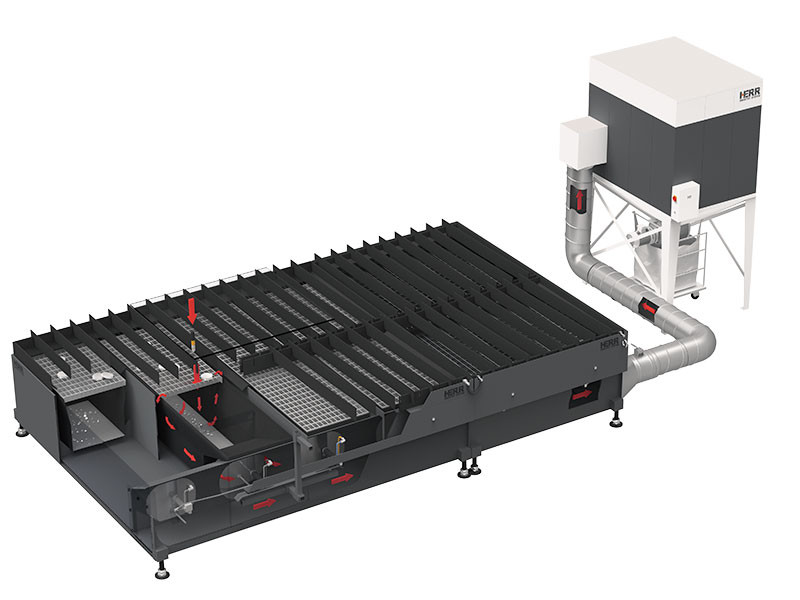

Complete system with table, filter system, fan and pipingAPPLICATION

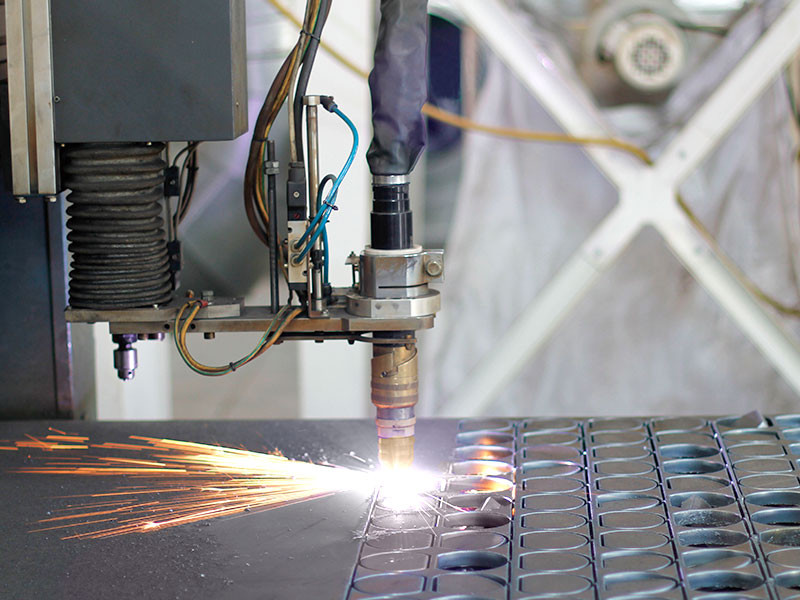

- automated cutting of sheet metal

MODULES OVERVIEW

| Width | Length 1.030mm | Length 2.060mm | Flap control |

| 1.100 mm | 460 kg | 870 kg | mech./via CNC |

| 1.600 mm | 760 kg | 1.260 kg | mech./via CNC |

| 1.800 mm | 855 kg | 1.417 kg | mech./via CNC |

| 2.100 mm | 920 kg | 1.660 kg | mech./via CNC |

| 2.600 mm | 1.200 kg | 2.050 kg | mech./via CNC |

| 3.100 mm | 1.300 kg | 2.150 kg | mech./via CNC |

| 3.200 mm | 1.400 kg | 2.200 kg | mechanical only |

We'll solve your special cutting needs with pleasure and competence - contact us!

PlasVent: your cutting needes - achieved!

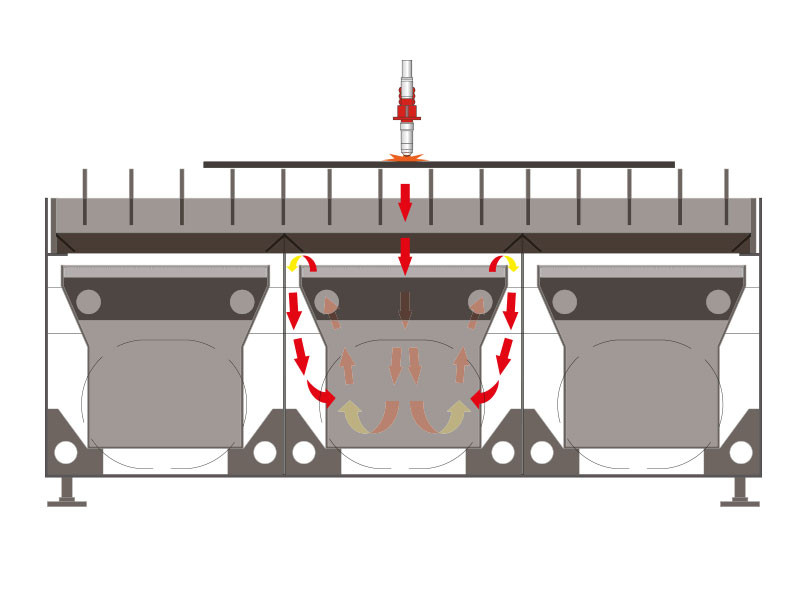

Besides the cutting machine in their entirety and the used material, the cutting table is responsible in major case for the quality of the cutted parts. It must therefore be worked sufficiently precise to achieve the desired quality. Moreover, the cutting table has to ensure effective and efficient removal of contaminated air.

Only in combination with a harmonized on the table and machine filter system and a suitable fan the desired effect, the effective protection of employees and machines, can be achieved. You receive from HERR a complete system consisting of table, filter system, fan and piping. Additional demands on a good cutting table are derived from ease of installation, further care and maintenance and also energy consumption.

PlasVent cutting tables from HERR are manufactured from high quality components and meet these demands. The tables are modular and can be adapted to local conditions. The modular design also allows easy transport and time-saving installation. The PlasVent cutting table needs low maintenance. Compressed air lines inside are made of copper and the longevity of the other materials used, effectively reduce follow-up costs in the form of repairs and spare parts.

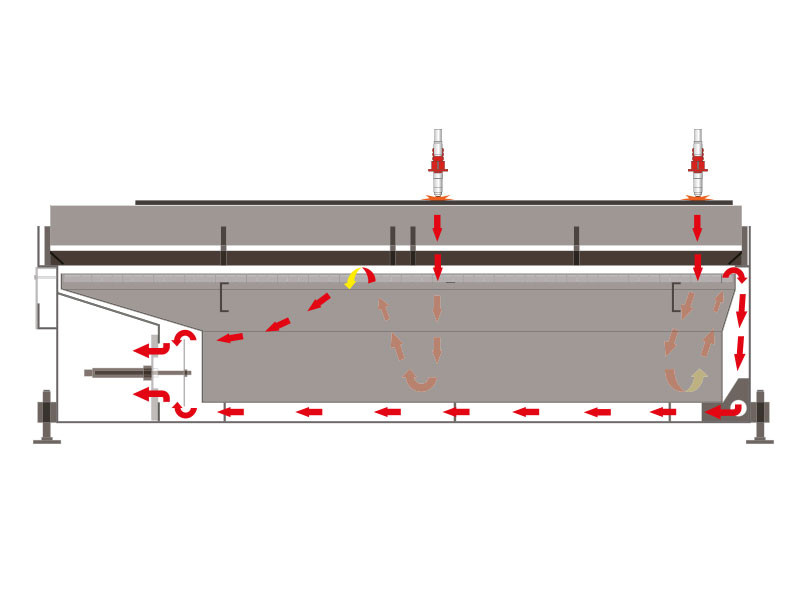

The optimized exhaust duct, the design of the flaps and the massive construction reduce the need for compressed air and save energy.

Easy cleaning and maintenance

For exchange of cutting slats, the cutting support can be lifted as a whole using the designated eyelets. Due to this sophisticated design, the slats can be exchanged in comfortable and timesaving way. The ease of cleaning and maintenance are further advantages of PlasVent cutting tables.

Simple and quick installation

The tables have lifting eyes and can thus be easily and safely lifted into place. By 100mm height-adjustable feet the leveling of the table is simplified and saves installation time.

The compressed air connection of the table modules can be achieved cleanly and quickly thanks to quick connectors.

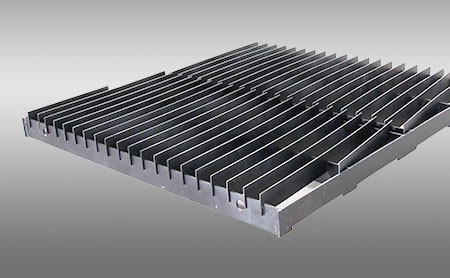

Small parts grid

Optionally available is a small parts grid. The grid prevents small work pieces from falling into the slag boxes preventing a time consuming recovery. Due to its solid design the grid is suitable for plasma and oxy-fuel cutting. For a table module of a length of 1,030mm two pieces, for a table module of a length of 2,060mm four pieces are needed.

Cutting grids

For a perfect cutting result, the choice of a suitable cutting support and slats is indispensable. HERR PlasVent cutting tables are equipped as standard with a cutting support including 5mm thick slats. This support is suitable for continuous plasma and oxyfuel cutting applications up to 150mm. For cutting of thin sheets up to 30mm with plasma, a cutting support with 1.5mm thick slats is available. When cutting thick plates (≥150mm) we recommend cutting support with stronger slats or cast iron tips. For such applications, HERR has cutting supports with 8mm or 10mm thick slats in the delivery range. Cutting supports with cast iron tips are available upon request.

Opening of the exhaust flaps

The opening of the exhaust flaps can be carried out either mechanically, controlled by a mounted on the cutting machine sledge or by CNC. For the mechanical version, the sledge can be easily adjusted to fit to the cutting machine. If opening of the exhaust flaps is controlled by CNC, the necessary cables for connection to the control box are included in the scope of supply. The advantages of the CNC controlled exhaust flap opening are the reduction of wear parts and maintenance costs.